What is a diaphragm pump?

Diaphragm pump is the most popular type of pump from the category of positive displacement pump. A Diaphragm Pump is also known as a membrane pump, air-operated double diaphragm pump (AODD) or pneumatic diaphragm pump. For pumping a fluid, a diaphragm pump uses a combination of the reciprocating action of the diaphragm made of Teflon, thermoplastic, or rubber with the corresponding valves (globe valves, flap valves, butterfly valves, check valves or any other type of valves) on both sides of the diaphragm.

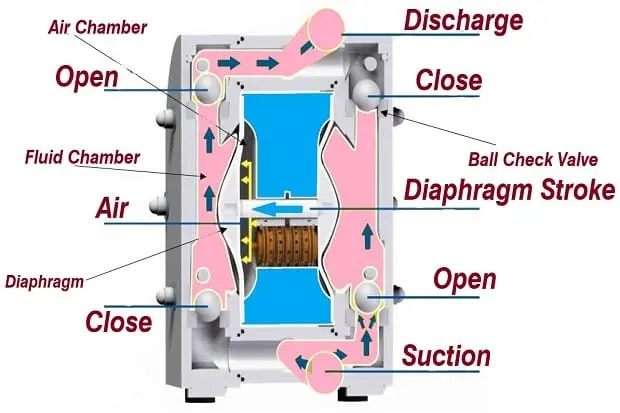

In general, the working principle of a diaphragm pump uses two adaptable diaphragms that have back and forth movements that create a temporary cavity and this section pumps in and expels the liquid through the pump. The two diaphragms function as a partition barrier between the liquid and the air.

In the initial stroke, the two diaphragms are linked through a shaft via the center chamber, here air valve is also positioned. The main functionality of this air valve is to let the compressed air towards the first diaphragm one thus allows to be close to the center chamber. The first diaphragm develops a press stroke that pulls the fluid out from the pump. Whereas the next diaphragm during this time performs a suction stroke. The air which is in the rear section of the second diaphragm makes environmental pressure to push close the liquid towards suction.

The most common type of diaphragm pump is air operated diaphragm pump and these devices utilize compressed air as the power resource. In this type also, a diaphragm has two sections along with inlet and outlet check valves in every section. Through the air spool valve, sir circulates from one section to other and the spool valve is constructed into the pump. The circulation of air pulls out the liquid from one section and drives into the discharge piping whereas the other section is with liquid. In these devices, there will a little pulsation of the discharge movement. And this pulsation can be lessened through the utilization of dampeners in a piping way. These air operated diaphragm pumps will be available in the sizes of ¼” to 4” having low to high flow rates.

Advantages and Disadvantages of Diaphragm Pumps

The diaphragm pump advantages include the following.

- These pumps are not expensive due to the proper maintenance

- Self-priming

- Explosion proof

- Changeable flow rate and expulsion pressure

- Portable

- Easy installation

- They can operate in the long term

- These are energy-efficient as they apply extra force while the forward hit of the pump.

- These are well suited for pumping chemicals otherwise other harming fluids

- These pumps are suitable to conquer standing force within the flow line.

- Most of the diaphragm pumps need approximately 20 typical cubic-feet for each minute & 100 PSI of air intake for operating powerfully.

- These pumps are inclined not to push extremely accurate at their base end.

- This diaphragm pump pulsates, so a dampener has to be fixed on top of the pump to decrease pulsing.

1). Can you run a diaphragm pump dry?

For some period of time, running dry diaphragm pumps will not show any kind of harmful effects, while operating for a long period will damage the parts of the device.

2). Are diaphragm pumps reversible?

Yes, diaphragm pumps hold the ability to function against the pressure gradient and so they are reversible.

3). Can diaphragm pumps pump air?

Yes, air operated diaphragm pumps can pump air making compressed air as their power supply.

4). What happens if a pump is not primed?

Before the operation of the pump, they have to be primed or they might not function efficiently.

5). What is the max head of a pump?

The point where the pressure is zero is considered to be the maximum head of the pump.