The wetted parts of pumps may be constructed from a number of materials:

- Metals (for example: cast iron, stainless steel, nickel alloys) for casings and other components where mechanical strength is important.

- Thermoplastics (for example: PTFE, PVDF, PP) for casings, linings, bearings, gaskets and seals when dealing with corrosive chemicals.

- Ceramics (for example: alumina, silicon carbide) for seal faces and bearings.

- Elastomers (for example: Buna N®, Viton®) for flexible components such as shaft seals and O-rings.

What is corrosion?

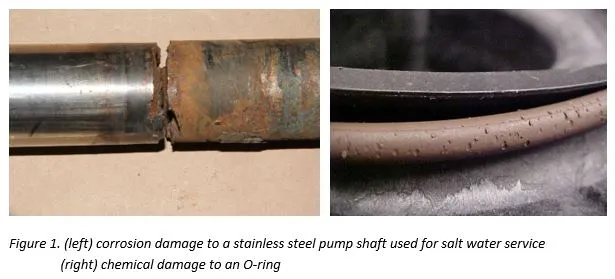

Corrosion in pumps arises from chemical reactions in between the pumped liquid as well as exposed steel surface areas. It causes damaged efficiency as well as boosted upkeep prices. In extreme cases, corrosion can trigger the premature failure of equipment. In terms of the chemistry, rust is the result of metals being oxidised. Iron, for example, will readily corrode in the visibility of air and also dampness to develop iron oxide (rust). This does not form a solid bond with the underlying metal and also exfoliate to subject even more bare metal to proceeding rust. Stainless-steel and other alloys offer better corrosion resistance due to the fact that they have a safety layer of chromic as well as other oxides that do bond highly to the underlying steel.

How does corrosion or deterioration happen?

Pumps experience a number of various types of corrosion: Uniform deterioration is a consistent and also consistent damage over the entire surface of a subjected metal element. It is foreseeable, so the functional lifetime of the part can be approximated from test outcomes or common deterioration charts. Uniform deterioration can be minimised by covering the steel surface areas with a safety layer (metal or non-metallic) or by installing a pump created from extra resistant materials such as stainless-steel or nickel-based superalloys.

Galvanic corrosion takes place when there are combinations of different bare metal surfaces (for instance, stainless-steel as well as copper) in the existence of an electrolytic tool such as an acid or alkali. This essentially sets up a battery with cost and material moved in between the various metal surface areas. To prevent or reduce galvanic corrosion, it is essential to analyze the products made use of throughout a system: shutoffs, piping as well as pump components.

Matching corrosion is a localized effect, normally following damage to a safety surface area layer. Once revealed, the underlying steel begins to corrode, leaving irregular pits with sharp sides. This can be a trouble when a fluid consists of abrasive bits and it is aggravated at high circulation prices. Cavitation can additionally promote pitting corrosion.

Stress corrosion splitting is a localised result prompted by stress and anxieties in an element. The mix of mechanical tension as well as deterioration might lead to fracturing.

Intergranular corrosion is a degradation of steel around grain limits. It is more generally discovered in stainless-steel pump spreadings or around welds.

Crevice corrosion develops because of stagnant pools of fluid retained in restricted areas, for example, around flanges. It is specifically an issue when pumps are only made use of periodically.

Microbiologically affected deterioration (MIC) can be an issue in pumps that manage without treatment water. Relying on the problems, some germs can generate or promote corrosion.

What is cast iron?

Cast iron is generally used to manufacture pump housings as a result of its inexpensive and also the convenience with which parts can be cast as well as machined. When used in applications with water or liquid services with pH worths in between 6 as well as 10, cast iron, which contains around 4% carbon, quickly obtains a safety graphite layer. As a matter of fact, poorer quality cast iron with a higher carbon web content is a lot more resistant to corrosion than steel.

What is stainless steel?

Stainless-steel consists of a significant percentage of chromium (a minimum of 15%), which creates a thin, inert oxide layer on the surface. Unlike iron oxide, this binds strongly to the steel surface and as a result protects the underlying metal in settings that would be highly harsh for actors iron or carbon steel. Other aspects such as nickel, manganese as well as molybdenum may also be added to stainless-steel to additionally improve corrosion resistance. Under the right conditions, the safety oxide layer is self-repairing if it is scraped or harmed.

There are four primary types of stainless-steel based upon their crystal frameworks: austenitic, ferritic, martensitic as well as duplex. One of the most common sorts of stainless steel made use of in pump manufacture are the 300 collection in the austenitic household, especially 304 and also 316. The 304 quality contains 18% chromium and also 8-10% nickel. The 316 grade also consists of 2% molybdenum and also has greater resistance to acids and also to localized rust.

Cast iron, steel or stainless-steel?

In some cases, making use of carbon steel or actors iron is preferred to stainless steel for price reasons. Corrosion is accepted, modelled moderately precisely, and factored right into on-going maintenance as well as equipment replacement expenses. However, if the expected corrosion price is high and also seriously restricts life span, then stainless steel pumps, although more costly, might be cost-efficient in the long-term. It is necessary to select an ideal grade of stainless-steel for the specific application by describing compatibility charts and also consulting pump makers. If the pumped liquid includes solids, stainless-steel may go through sped up rust. Rough bits can harm stainless-steel's passive, protective layer exposing the underlying metal to deterioration.

What is a superalloy?

For dealing with caustic media such as acids and antacid, especially at raised temperatures, nickel-based "superalloys" have a greater resistance to rust than stainless steel. These alloys are generally known by their tradenames, for instance: HASTELOY ®, INCOLOY ®, INCONEL ®, as well as MONEL ®.

What is a thermoplastic?

Thermoplastics are resistant to many liquids that wear away steels. They are qualified by a capability to be softened by home heating and also cast right into complicated forms. It is as a result possible to mold individual elements or perhaps a whole pump instance. Mechanical toughness can be enhanced with fillers such as glass fibre. Nevertheless, physical residential or commercial properties are normally substandard to those of equivalent metal pumps.

PTFE (Teflon ® is an usual tradename) is utilized for lots of pump components including gaskets, seals and diaphragms because of its exceptional corrosion resistance as well as chemical inertness. Unlike the majority of thermoplastics, PTFE additionally has a broad operating temperature variety (up to 250 ° C).

How are pumps lined?

Numerous pump components (shafts, sleeves, bettors, piston poles, impellers, containment shells) can be coated with metallic, non-metallic and also ceramic compounds to achieve increased rust and also put on resistance. Coatings can likewise be used to fix broken or worn elements.

To apply a metallic coating, various techniques can be used:

- Thermal spray: a stream of molten particles, generated using an electric-arc, plasma or a combustion process, is projected onto the base material.

- Spray and fuse: the coating is sprayed in liquid form onto the component which is subsequently heated to 950°C or more to fuse the coating.

- Plasma transferred arc (PTA): a welding process with elements of both thermal spray and spray and fuse techniques.

- Laser cladding: similar to PTA but using a laser as the heat source.

| Major constituents (example tradenames) | Application and uses |

|---|---|

| Cobalt-Chrome-Tungsten alloys (e.g. Stellite/Wallex) |

Good corrosion and wear resistance |

| Nickel-based alloys (e.g. Colmoney) | Good resistance to corrosion and heat |

| Nickel-chromium-molybdenum alloy (Hastelloy®) |

Excellent resistance in oxidizing and reducing media, such as acids, even at elevated temperatures. High resistance to cracking, pitting and stress corrosion |

| Aluminium oxide/titanium dioxide (e.g. Amdry/Metco) | Range of ceramic powders applied by thermal spray, resistant to wear and good thermal and chemical resistance |

| Chromium oxide | Improves corrosion, abrasion and wear resistance |

| Tungsten carbide (UCAR LW-15) | High wear resistance (for applications below 500°C) |

Thermoplastics, such as PTFE, can also be applied as a protective layer over metal components. These are usually applied as a powder and then heated. During subsequent cooling, the coating hardens. Some thermoplastic coatings can be reheated to correct and seal any flaws.

The coatings can be applied by:

- Electrostatic spray: electrical charging is used to coat the powder on the metal surface and the component is then heated, causing the powder to melt and flow.

- Preheat spray application: the metal part is preheated, and the coating sprayed onto it. It immediately melts and flows over the heated surface.

- Dip coating/fluidized bed: Preheated parts are immersed in a fluidized thermoplastic powder coating which is attracted to and subsequently fuses to the heated surface.

Chemical compatibility charts are normally available from pump manufacturers. These describe the resistance of materials commonly used in pump construction to various chemicals. It is important to refer to these when selecting a pump to ensure that all wetted parts are chemically compatible with, and resistant to, the pumped medium. This can only be a guide as corrosion and, in the case of thermoplastics and elastomers, chemical damage such as softening or swelling, can vary widely with concentration, temperature, the presence of abrasives, impurities or entrained gases. It may be necessary to carry out tests under field conditions and to consult with pump manufacturers before committing to a system.

Table 2. Section of a chemical compatibility chart for Micropump’s range of gear pumps