An open impeller has vanes that are attached to a center hub and mounted directly onto a shaft. There is no wall surrounding the vanes which makes open impellers weaker than closed or semi-closed valves. Open impellers are normally faster and very easy to clean and repair. Normally small pumps are idle for open impellers. Besides, open impellers are the best at handling suspended solids and hence are idle for pumps that deal with such tasks.

Semi-open impellers have a back-wall shroud that adds mechanical strength to the vanes, whilst remaining open on the other side. They are somewhat of a middle ground between open and closed impellers in terms of efficiency and NPSHr, making them suited to medium sized pumps with a small amount of soft solids. It’s important to note with semi-open impellers that the clearance between the vanes and the pump casing needs to be small, as if too large slippage and recirculation will occur.

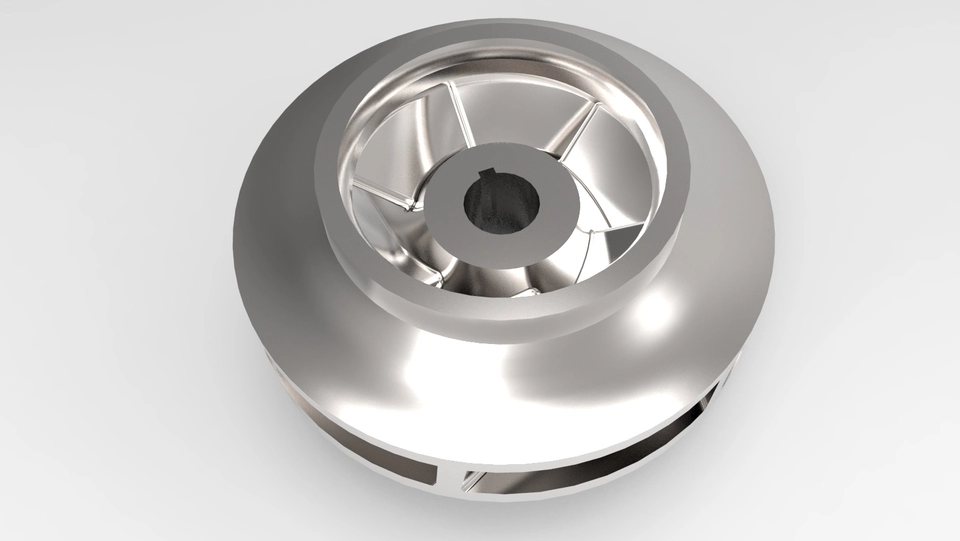

These consist of a back and front wall that surrounds the vanes, which increases their strength. These are specifically used in larger pumps and they are idle in applications that involve liquids and fluids with suspended solids.These are normally used when dealing with a clear liquid. They are not good when it comes to solids as they are so difficult to clean when they become clogged.